Measuring Mass Flow of Air in a Duct with a Multivariable Transmitter

When measuring the mass flow of air flow in a duct or pipe, using the correct flow element is half the battle. After deciding that using a differential pressure device like a Velocity Averaging Pitot is the right way to go, getting the correct instrumentation to measure that differential pressure is not something that every transmitter can do.

In typical industrial, combustion, and power generation applications, the differential pressure to be measured ranges from a high of 8 to 10 inches of water column down to 0.25 inch of water column or even less. Getting a transmitter that can measure these ranges and have a turndown that can measure the low end accurately usually requires getting a laboratory type of transmitter, rather than an industrial differential pressure transmitter. These are typically not satisfactory for these types of applications, so most users go with an industrial transmitter that has a very large URL (upper range limit). This is not by design or desire, but typical industrial transmitters have an upper range of 25 inches of water column or even 40-50 inches of water column! To ensure that they can measure the maximum differential, they will have these transmitters scaled down, making their accuracy at these lower range or draft range differential pressures very poor.

To complicate the challenge, to get an accurate mass flow measurement, measuring the temperature and static or absolute pressure is required so as to compute the density of the air. Without getting separate instruments for each of these variables, which can be very costly, most users get a multivariable transmitter. Most industrial multivariable pressure transmitters not only have a very high URL for the differential pressure, but also do for the static or absolute pressure. They are designed to be used in the widest possible array of applications, instead of being dedicated to the ranges needed for most industrial, combustion, and power generation applications.

On top of the high upper range on the sensors, these devices are over complicated, and require expensive software to be setup and configured. Again, since they are used for a wide array of applications. They also typically have a diaphragm seal, which protects the sensors from contaminants and condensation in the impulse lines. This is great for dealing with corrosive environments and dangerous gases, but for typical air flow measurement in a duct, the diaphragm seal only complicates these transmitters and adversely affects their turndown and accuracy.

So, the question remains, how do you get an accurate differential measurement on low end pressures, get a computed density from live variables, and have a simplified interface while providing the mass flow??

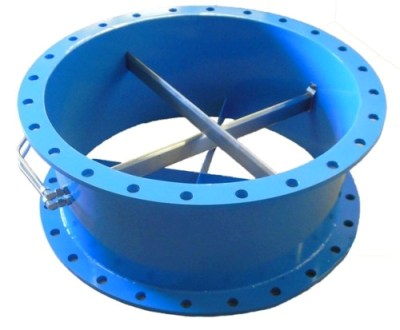

|

| VAP³ Velocity Averaging Pitot |

To complicate the challenge, to get an accurate mass flow measurement, measuring the temperature and static or absolute pressure is required so as to compute the density of the air. Without getting separate instruments for each of these variables, which can be very costly, most users get a multivariable transmitter. Most industrial multivariable pressure transmitters not only have a very high URL for the differential pressure, but also do for the static or absolute pressure. They are designed to be used in the widest possible array of applications, instead of being dedicated to the ranges needed for most industrial, combustion, and power generation applications.

On top of the high upper range on the sensors, these devices are over complicated, and require expensive software to be setup and configured. Again, since they are used for a wide array of applications. They also typically have a diaphragm seal, which protects the sensors from contaminants and condensation in the impulse lines. This is great for dealing with corrosive environments and dangerous gases, but for typical air flow measurement in a duct, the diaphragm seal only complicates these transmitters and adversely affects their turndown and accuracy.

So, the question remains, how do you get an accurate differential measurement on low end pressures, get a computed density from live variables, and have a simplified interface while providing the mass flow??

Finally the answer has arrived!

|

| QVT Multivariable Transmitter |

The QVT is a loop powdered microprocessor based multivariable smart transmitter, which simultaneously measure the differential pressure, absolute pressure, and temperature. It provides a live density computation and mass flow rate computation, which is compensated for the density it calculated. It is designed to be used specifically in these types of low differential pressure applications, have a typical URL of 8 inches of water column, while being able to be set to a full scale of 0.8 inches of water column.

The unit has a sealed sensor head connected to a cast aluminum industrial enclosure, making it perfect for industrial locations. The device can be configured with a 3 or 5 port manifold and a Transmitter Mounted Purge, which is a low volume continuous purge.

Coupled with the VAP³ Insertion Probes, Ducted Section (DSV) unit, or High Beta (HBP or HBE) unit, a complete flow measurement solution is now available for industrial, combustion, or power generation applications.

For more information, check out our website easterninstruments.com, call us at 910-392-2490, or email us at sales@easterninstruments.com today!