When it comes to measuring the flow rate of air or gas in a duct, there are many different devices used. For example, there are thermal sensors, hot wire anemometers, rotating vane anemometers, static pressure drop devices (venturi, orifice plate), and differential pressure devices (pitot, annubar, primary element). The most widely used and considered a true measurement of the flow is the differential pressure device. The most widely used differential pressure device is a velocity averaging pitot tube.

The velocity averaging pitot tube is a device that when inserted into the air or gas flow stream, provides a high pressure measurement port and a low pressure measurement port. The high pressure port measures the total pressure created when the air or gas stream impacts the port, where the low pressure port typically measure the static pressure in the duct.

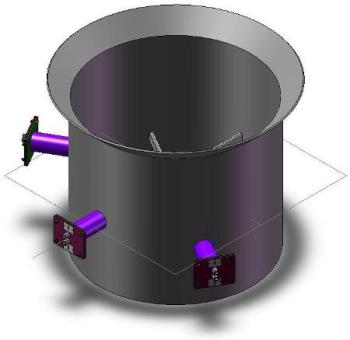

|

| VAP³ Velocity Averaging Pitot Tube from Eastern Instruments |

The difference between the two pressures, called the dynamic pressure, can be used to calculate the flow in the duct using the Bernoulli principle and equation. This equation, in a simplified form when using a pitot tube, states that the velocity in a duct is equal to the square root of two times the differential pressure, divided by the density of the air or gas.

For the best results using a pitot tube, there should be an array of probes used to ensure that there is an adequate traversing across the duct cross-section. In addition, the individual pitot tubes would have multiple ports, thus averaging the pressure measurement in any one probe and then in the array of probes.

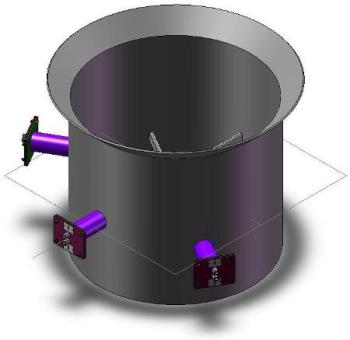

|

| VAP³ Pitots in an Array in a Circular Duct |

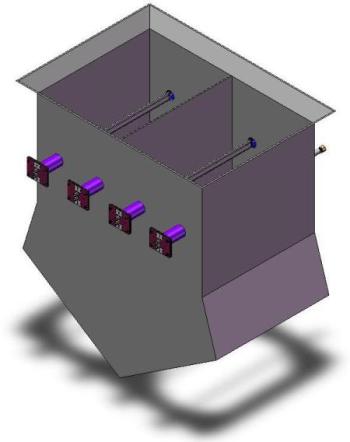

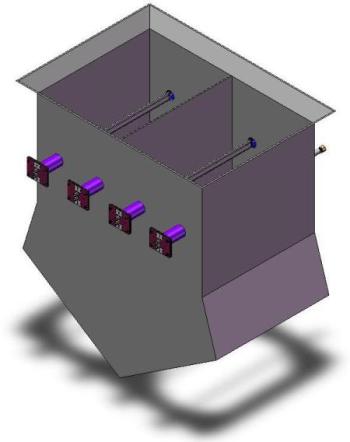

|

| VAP³ Pitots in an Array in a Square/Rectangular Duct |

Not all pitot tubes are created equally. Most are just a cylindrical tube or set of tubes that have holes in them, or some modification of the cylindrical design. The flow profile around these tubes can be distorted and even non-repeatable, causing them to have a calibration factor or "K" factor based on flow rate or velocity of the air or gas stream.

In order to get the best result and not have an affect based on the flow around the pitot tube, the pitot tube should have a cross-section such that the flow pattern is not disturbed. Such is the case with the

VAP³ Velocity Averaging Pitot Tube from Eastern Instruments. Its patented design allows the flow profile to run parallel around it, before combining together behind the probe. This not only allows the probe to get an accurate differential pressure measurement, but makes the pitot velocity independent, eliminating the need for the K factor.

While velocity averaging pitots can provide a very accurate way to obtain the flow rate in a duct, they are susceptible to particulate in the air or gas stream. Most pitots can plug when the particulate is large or if it is heavily particulate laden. The high port will plug, causing an error in the differential pressure measurement. The typical way to combat this issue is to use a high pressure purge or blow out, but these systems can be complicated and expensive to run. The

VAP³ PA Pitot from Eastern Instruments uses that same patented design that allows it to be independent of velocity yet also provides a plug resistant configuration where the high port is not in the direct impact of the air or gas stream, thus making it plug resistant.

|

| VAP³ Velocity Averaging Pitot in the SA (Clean Air/Gas) and the PA (Particulate Laden/Plug Resistant) |

To learn more about velocity averaging pitots and the unique design of the VAP³ pitot from Eastern Instruments, visit our website at

easterninstruments.com, give us a call at 910-392-2490, or email us at

sales@easterninstruments.com.