Solids Flow Measurement Issues - Accuracy Issues Related to Pulsating Flow

There are many different ways to move solid materials through a process, ranging from belt conveyors, vibratory conveyors, and pneumatic systems, to bucket conveyors/elevators and screw conveyors. Many of these devices are great for moving the product, but if you need to measure the mass flow rate or control the flow rate, pulsations created by some of these devices can cause major problems.

Devices like bucket conveyors/elevators, rotary valves, and screw conveyors have pockets, flights, or buckets that help to collect the product and move it through the device. These create pulses or slugs of flow, some of which can be very large and there can be seconds or even moments where there is no flow at all between slugs.

Most mass flow meters require that pulsations be mechanically smoothed if at all possible, because they cannot deal with the pulsations when measuring the flow and computing the totalization. This is typically because the device is averaging or slow in its response of measurement, so some information would be missed or misunderstood by the meter with these pulsating flows. The product path usually has to include a long intake to the device to smooth out and present the product to the device. This make the device take up more valuable space in the process.

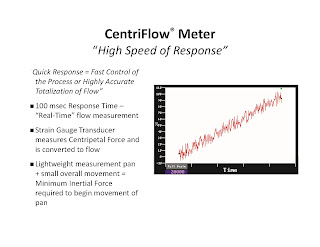

When nothing can be done to change the flow pulsations, a common practice is to electronically average the flow so that the pulsations are mitigated, providing a "smooth" flow output from the meter. This practice can be detrimental to a control scheme, since this time averaging creates delay in the control, making the whole process suffer when changes in flow exist. The best solution would be to have a flow meter that has a high speed of response to measure the pulsations without this delay, providing an instantaneous output signal. If a "smoothed" or averaged flow rate is desired for display purposes, then the device should have this capability without affecting the output.

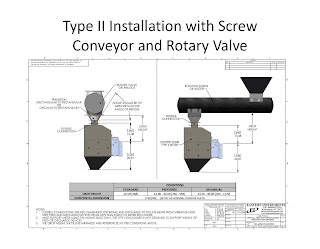

Once such device is the CentriFlow Meter from Eastern Instruments. The Type II is suited perfectly for installation under these types of devices. The unit does not require a long straight run, and in most circumstances, it is recommended that the device be installed directly under the feed device, requiring only a small, short transition to the intake of the housing. The key is the meter's fast response, being able to see flow changes every 100 milliseconds, thus providing a highly accurate flow rate and totalization regardless of the pulsations present.

For more information on the CentriFlow Meter or any other product by Eastern Instruments, please visit our site easterninstruments.com, call us at 910-392-2490, or email us at sales@easterninstruments.com.

Devices like bucket conveyors/elevators, rotary valves, and screw conveyors have pockets, flights, or buckets that help to collect the product and move it through the device. These create pulses or slugs of flow, some of which can be very large and there can be seconds or even moments where there is no flow at all between slugs.

Most mass flow meters require that pulsations be mechanically smoothed if at all possible, because they cannot deal with the pulsations when measuring the flow and computing the totalization. This is typically because the device is averaging or slow in its response of measurement, so some information would be missed or misunderstood by the meter with these pulsating flows. The product path usually has to include a long intake to the device to smooth out and present the product to the device. This make the device take up more valuable space in the process.

|

| CentriFlow Solids Flow Meter has a High Speed of Response to deal with Pulsating Flow |

When nothing can be done to change the flow pulsations, a common practice is to electronically average the flow so that the pulsations are mitigated, providing a "smooth" flow output from the meter. This practice can be detrimental to a control scheme, since this time averaging creates delay in the control, making the whole process suffer when changes in flow exist. The best solution would be to have a flow meter that has a high speed of response to measure the pulsations without this delay, providing an instantaneous output signal. If a "smoothed" or averaged flow rate is desired for display purposes, then the device should have this capability without affecting the output.

Once such device is the CentriFlow Meter from Eastern Instruments. The Type II is suited perfectly for installation under these types of devices. The unit does not require a long straight run, and in most circumstances, it is recommended that the device be installed directly under the feed device, requiring only a small, short transition to the intake of the housing. The key is the meter's fast response, being able to see flow changes every 100 milliseconds, thus providing a highly accurate flow rate and totalization regardless of the pulsations present.

|

| CentriFlow Solids Flow Meter installation under Screw Conveyor or Rotary Valve |