Measuring the Mass Flow of Difficult to Handle Powders with the CentriFlow Meter

Measuring the mass flow rate and totalization of a dry solid material can be difficult when that product is a hard to handle powder. Product characteristics like particle size, cohesiveness, flowability, bulk density can all affect the accuracy of the mass flow measurement of a powder. Below we will look at these characteristics in more detail and discuss how the CentriFlow Solid Mass Flow Meter is suited to deal with issues from these characteristics, making them non-issues or helping to eliminated/overcome them to get the best accuracy possible.

Particle Size:

Particle size can become an issue when a material's particles get down to the powder regime, around 0.0394" or 1000 microns (18 mesh) and smaller. The smaller the particle, usually the more trouble it can be to handle and therefore to measure. However, there are definitely small particles that are not an issue, like sand, which can fall into the 0.0098" or 250 micron (60 mesh) size, but it is a very free flow granule and does not typically exhibit "powder-like" issues. Very small particles, tend to dust greatly, can cause explosion hazards, and can build-up on surfaces, especially where the measurement is concerned.

Cohesiveness:

Cohesiveness is a way to describe how the product particles bind to themselves, and therefore to other materials. Products like sand can be categorized as having no cohesiveness since you can grab a hand full of the product and it will not stick together. Titanium Dioxide would be an example of a product that can be categorized as being very cohesive. Grabbing a hand full of TiO2 most likely will end up with you have a ball or cake of product, with residue all over your hand. Products like Flour, Gypsum, Limestone and others can be categorized as having slight cohesiveness and sometimes that varies from product to product.

Flowability:

Flowability can be described as a products ability to flow or slide off a plate when tipped at an angle. For example, if you take sand and pile it on a metal plate, when you tilt the plate, it will most likely begin to slide off the plate when the plate is tilted at an angle of 30° to 45°. This would be considered average flowability. Talc or TiO2, will most likely not slide at an angle of 45°, but will need something higher. This can be categorized a having low flowability. Carbon Black is very flowable, almost like water, and will most likely slide off the plate at an angle less than 20°. This can be categorized as high or very free flowing. There are a number of products that will slide off the plate at an angle less than 30° but more than 20°, and these can be categorized as above average flowability.

Bulk Density:

Bulk Density is the weight per volume of the bulk of material flow that a mass flow meter will see when it goes through the device. Depending on the product, there are a number of methods for computing the bulk density ranging from just putting product into a 1 cubic foot container and weighing it (remember to tare out the container and just get the weight of the product), using a flask filled up to a specific level, or using a bulk density sampling system. The bulk density itself is not an issue, but what becomes an issue is knowing the bulk density when the product is flowing. Since the bulk density of a powder can change rapidly as the product is moved within a process, it is very difficult to know the "actual" bulk density of the flowing product. These changes in bulk density often come from aeration of the product as it is moved.

Meter Construction:

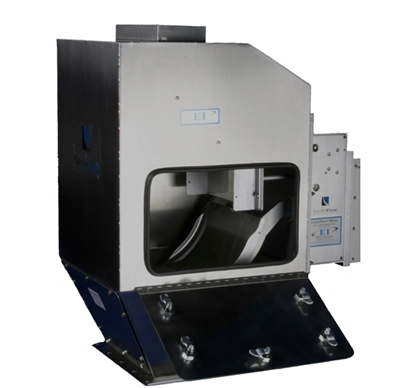

The CentriFlow Meter from Eastern Instruments has many features that have been designed with hard to handle powders in mind. Standard construction of the flow paths using polished stainless steel with rounded corners helps to keep powders moving through the meter so that not only does it not plug the system, but the product presentation is optimized to get the highest accuracy. The Type II housing is designed to contain powders, the dust created by them, and prevent plugging of clumps of cohesive products. The internal Diverter is positioned and angled to get the maximum angle for difficult flowing products. Many flow surface option are available which maximize slickness or reduce/eliminate sticking.

VibraWeigh Option:

The VibraWeigh option is an integrated vibration device that shake the Measurement Pan, helping to keep products flowing through it, while not interfering with the measurement. This vibration is factory set to optimize the frequency and amplitude of the vibration to get the best results.

Pulsed Air Option:

The Pulsed Air option is a specialized air bar system that is positioned to blow off the Measurement Pan on a periodic basis. This blast is at a high pressure, short duration, and optimum location so that most cohesive and dusty products are no match for it. During the blast, the electronics monitors the flow meter's signal and ensures that the blast does not affect the measurement accuracy.

Hazardous Locations:

When the meter needs to be used to measure the flow rate of a powder that creates enough dust potential to be hazardous or explosive, options like a Purge/Pressurization System or Intrinsic Safety Barriers. With the Purge/Pressurization System, the meter and its electronics can be located in a hazardous area by creating a pressurized loop between the components, keeping explosive dust out of the areas where electronics are contained. With the Intrinsic Safety Barriers, the meter can be in the hazardous location, while the electronics are in an isolated safe zone. The barriers prevent a spark from being made and igniting the dust.

Testing:

Eastern Instruments offers free testing of a material sample to determine the product characteristics, observe product flow in a CentriFlow Meter, and help to configuration/optimize a meter to obtain the highest accuracy. Many product tests exist on our website Flow Watchers - Application and Test Videos

Look for the items mentioned above and more by visiting our website easterninstruments.com, calling us at 910-392-2490, emailing sales@easterninstruments.com or by clicking on the links below:

https://easterninstruments.com/products/centriflow/Type%20II%20Powder.html

https://easterninstruments.com/products/centriflow/Options.html

https://easterninstruments.com/services/testing.html

|

| CentriFlow Meter - Type II Configuration |

Particle Size:

Particle size can become an issue when a material's particles get down to the powder regime, around 0.0394" or 1000 microns (18 mesh) and smaller. The smaller the particle, usually the more trouble it can be to handle and therefore to measure. However, there are definitely small particles that are not an issue, like sand, which can fall into the 0.0098" or 250 micron (60 mesh) size, but it is a very free flow granule and does not typically exhibit "powder-like" issues. Very small particles, tend to dust greatly, can cause explosion hazards, and can build-up on surfaces, especially where the measurement is concerned.

Cohesiveness:

Cohesiveness is a way to describe how the product particles bind to themselves, and therefore to other materials. Products like sand can be categorized as having no cohesiveness since you can grab a hand full of the product and it will not stick together. Titanium Dioxide would be an example of a product that can be categorized as being very cohesive. Grabbing a hand full of TiO2 most likely will end up with you have a ball or cake of product, with residue all over your hand. Products like Flour, Gypsum, Limestone and others can be categorized as having slight cohesiveness and sometimes that varies from product to product.

Flowability:

Flowability can be described as a products ability to flow or slide off a plate when tipped at an angle. For example, if you take sand and pile it on a metal plate, when you tilt the plate, it will most likely begin to slide off the plate when the plate is tilted at an angle of 30° to 45°. This would be considered average flowability. Talc or TiO2, will most likely not slide at an angle of 45°, but will need something higher. This can be categorized a having low flowability. Carbon Black is very flowable, almost like water, and will most likely slide off the plate at an angle less than 20°. This can be categorized as high or very free flowing. There are a number of products that will slide off the plate at an angle less than 30° but more than 20°, and these can be categorized as above average flowability.

Bulk Density:

Bulk Density is the weight per volume of the bulk of material flow that a mass flow meter will see when it goes through the device. Depending on the product, there are a number of methods for computing the bulk density ranging from just putting product into a 1 cubic foot container and weighing it (remember to tare out the container and just get the weight of the product), using a flask filled up to a specific level, or using a bulk density sampling system. The bulk density itself is not an issue, but what becomes an issue is knowing the bulk density when the product is flowing. Since the bulk density of a powder can change rapidly as the product is moved within a process, it is very difficult to know the "actual" bulk density of the flowing product. These changes in bulk density often come from aeration of the product as it is moved.

Meter Construction:

The CentriFlow Meter from Eastern Instruments has many features that have been designed with hard to handle powders in mind. Standard construction of the flow paths using polished stainless steel with rounded corners helps to keep powders moving through the meter so that not only does it not plug the system, but the product presentation is optimized to get the highest accuracy. The Type II housing is designed to contain powders, the dust created by them, and prevent plugging of clumps of cohesive products. The internal Diverter is positioned and angled to get the maximum angle for difficult flowing products. Many flow surface option are available which maximize slickness or reduce/eliminate sticking.

VibraWeigh Option:

The VibraWeigh option is an integrated vibration device that shake the Measurement Pan, helping to keep products flowing through it, while not interfering with the measurement. This vibration is factory set to optimize the frequency and amplitude of the vibration to get the best results.

Pulsed Air Option:

The Pulsed Air option is a specialized air bar system that is positioned to blow off the Measurement Pan on a periodic basis. This blast is at a high pressure, short duration, and optimum location so that most cohesive and dusty products are no match for it. During the blast, the electronics monitors the flow meter's signal and ensures that the blast does not affect the measurement accuracy.

Hazardous Locations:

When the meter needs to be used to measure the flow rate of a powder that creates enough dust potential to be hazardous or explosive, options like a Purge/Pressurization System or Intrinsic Safety Barriers. With the Purge/Pressurization System, the meter and its electronics can be located in a hazardous area by creating a pressurized loop between the components, keeping explosive dust out of the areas where electronics are contained. With the Intrinsic Safety Barriers, the meter can be in the hazardous location, while the electronics are in an isolated safe zone. The barriers prevent a spark from being made and igniting the dust.

Testing:

Eastern Instruments offers free testing of a material sample to determine the product characteristics, observe product flow in a CentriFlow Meter, and help to configuration/optimize a meter to obtain the highest accuracy. Many product tests exist on our website Flow Watchers - Application and Test Videos

Look for the items mentioned above and more by visiting our website easterninstruments.com, calling us at 910-392-2490, emailing sales@easterninstruments.com or by clicking on the links below:

https://easterninstruments.com/products/centriflow/Type%20II%20Powder.html

https://easterninstruments.com/products/centriflow/Options.html

https://easterninstruments.com/services/testing.html